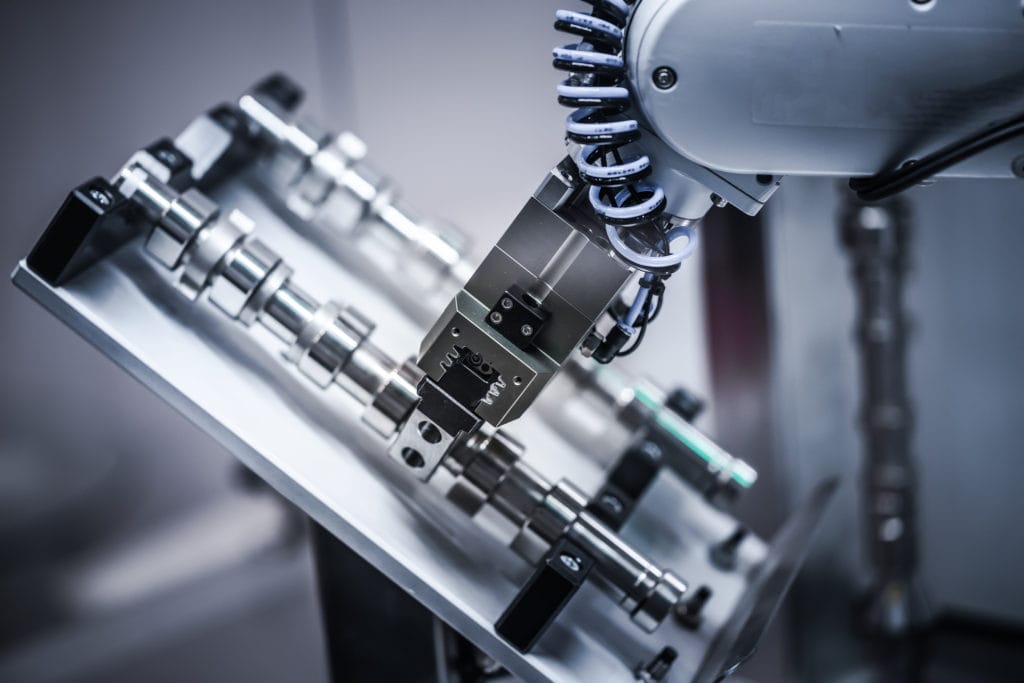

‘Daisy’, the disassembling robot, is Apple’s answer to reclaiming the valuable materials that go into the creation of nearly every Apple mobile and tablet device. Aluminum, cobalt, gold, silver, platinum, and many other valuable metals and rare earth can be extracted using this useful technology. Daisy’s efficiency is punctuated by an exceptional rate of recovery, disassembling, and collecting materials from outdated devices at the rate of 200 iPhones per hour.

Not only has the recycling robot enabled Apple to recover these valuable resources, but the machine’s creation process has yielded valuable information on recycling many of these materials in a cleaner and more efficient manner. New processes have eliminated the need to introduce contaminants and other dangerous substances into the recycling process, leading to an unsullied recycling process all around.

Daisy is not the first iteration of a mechanical recycler, though. Liam was the predecessor announced by Apple back in 2016. A very specialized robot, Liam was designed to specifically disassemble iPhones to access the recyclable materials inside. Some of the crucial components Liam sought, and Daisy seeks, out in each iPhone carcass include cobalt and lithium from the phone’s battery, gold and copper from the camera, silver and platinum from the device’s logic board, and aluminum from the enclosure.

Additional Charity With Apple’s GiveBack

Alongside the Daisy announcement, which coincided with Earth Day, Apple has announced the commitment to match customers’ turn-ins of devices with charitable contributions to the Conservation International environmental non-profit based in Virginia until April 30th. Some devices being turned in will even knab in-store gift cards and credit for those donating.

The press release detailing Daisy and Earth Day campaigns from Apple, along with all media associated with the announcement, can be found in the Apple Newsroom.

Cleaner Streams Of Recycling With Material Recovery Facilities

Daisy’s announcement is just one of the many emerging advancements taking place in the world of Material Recovery Facilities (MRFs). The recent WasteExpo 2018 in Las Vegas highlighted many of the recent advancements in the world of cleaner recycling and material recovery in electronics recycling, cleaning and sorting equipment, and municipal recycling endeavors.

Robotics and Artificial intelligence, in particular, are assuming significantly larger roles in the advancement of recycling efforts, enabling greater efficiencies in:

- Heavy lifting

- No deviation due to fatigue

- Repetitive tasks

- Continuously high levels of concentration

- Purity rates and consistent and accurate identification of products

- Pre-emptively tracking and managing work

- Maximal operating time

- Evolutive identification of products and more meaningful data

- Reproductivity of results

- Reduced labor and training

- Lower operating costs

While these innovations in the field of material recovery have enabled companies like CleanRobotics, and AMP Robotics to function with greater efficiency, difficulties remain within the variety of materials flowing into the recycling stream. The resounding answer to the challenge emerges again and again with machine vision.

Material Recovery Pushes Advances In Machine Vision Systems

Coupled with robots on recycling conveyor systems, machine vision systems identify elements and materials according to several characteristics. Once identified, the robotic component will employ suction, grippers, and grabbers to remove materials from the conveyor and sort them accordingly, for either direct recycling or further disassembly, if necessary. Eagle Vision and Bulk Handling Systems are two entities addressing the need for more robust machine vision systems in MRFs.

Interconnectivity between MRF system components read as the Industrial Internet of things (IIoT), allows devices to “speak” with one another across the facility. The results can be presented as simply as “I’m getting too much plastic” to which screens can be adjusted to narrow or expand the flow of specific materials, according to Nathanaël Lortie, co-founder, and president of Eagle Vision.

With accuracy rates reaching upwards of 85 -95 percent, these robots and their associated systems far surpass the public shoddy-by-comparison 30 percent accuracy.

About Encompass Solutions

Encompass Solutions, Inc. is an ERP consulting firm that offers professional services in business consulting, project management, and software implementation. Whether undertaking full-scale implementation, integration, and renovation of existing systems or addressing emerging challenges in corporate and operational growth, Encompass provides a specialized approach to every client’s needs. As experts in identifying customer requirements and addressing them with the right solutions, we ensure our clients are equipped to match the pace of the Industry.