Automation trends have experienced a substantial boom over the past several years and things are only gaining momentum. We couldn’t possibly cover all the latest updates and emerging automation trends, so here are the 10 we believe to be the most exciting emerging trends in automation for 2018.

1. Industrial Internet Of Things (IIoT) Technology Bringing Down Overhead

Lower cost and higher-value products with the capability of connecting to existing infrastructure and relaying relevant performance data in real-time will continue to cut automation costs for operations, at scale. Higher-performance processors, detailed sensor equipment, more robust analytics software, ultra-precise vision systems, and cloud computing are only a few examples of IIoT tech that are shaking up automation in Industry 4.0.

The Industrial Internet of Things is an interconnected web of devices and processes that help to create the modern “smart factory” in the latest industrial revolution, referred to as Industry 4.0.

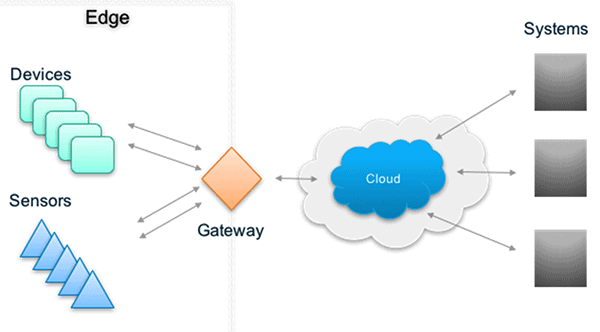

2. Automation Architecture Reorganized

The automation industry’s traditionally hierarchal architecture has commonly been represented by a pecking order that consists of several levels, most often referred to using the Purdue Reference Model (PRM) of control hierarchy.

However, technology has advanced to a degree that operations have permitted the architecture to circumvent entire levels altogether and enable more efficient and streamlined architecture. Using WEB services, among other protocols, controllers can communicate data from levels 0/1 directly to levels 4/5. The result is a leaner, more efficient, and more capable approach to automation, where concrete computing takes place in the cloud to provide power where it’s needed, at the edge. As a result, Operational and Information technologies are growing increasingly intertwined. Machine to machine communication protocols, like OPC Unified Architecture, B2MML, and PLCopen OPC UA, are feeding into the business intelligence loop which could significantly impact Manufacturing Execution Systems (MES) in the future.

Manufacturing Execution Systems (MES) control or influence a selection of enterprise-critical functionalities.

3. Edge Devices On The Rise

Improving performance and efficiency at network entry points, edge devices are the synapses of the IIoT. Including monitors and sensors, as well as a host of other intelligent technologies, these instruments communicate vital information between servers, enterprise systems, and other devices to tackle plant-level analytics, application virtualization, environmental data, and more to deploy services effectively and adjust operations in real-time.

4. Open-Source Architectures Will Improve Systems Integration

Adopting an open-source approach to the protocols through which systems intermingle will provide coordinated data exchange between manufacturing I/O, enterprise systems, and robotics to drive performance and improve operational autonomy. Open-source architectures will endeavor to diminish competition between vendors, as well as the use of the term incompatibility, and instead encourage vendors to distinguish themselves in the marketplace by offering the best value to the open-source community.

5. Portable Applications, Mobile Apps, And Multi-Touch Technology

Non-portable applications are a dying paradigm and are most effective at stifling innovation when it comes to automation. The interconnectivity between applications and hardware will take a prominent focus within the industry over the coming years with the call for new standards to be adopted coming from the automation’s research and engineering elites.

Mobility has increasingly become a defining trait of automation applications across industries. Mobile apps are already being relied on as fast and user-friendly means of accessing plant information with the push of a button. Mobile insights can save big on costs in time, labor, and maintenance as well when problems can be identified and addressed remotely.

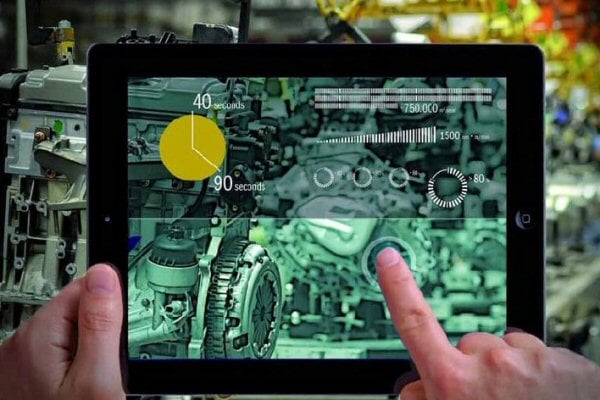

Multi-touch devices are increasingly being integrated into manufacturing operations with great success. Image: Kistler Group

Beyond interconnectivity between applications and robust programs through which humans interact with automation systems, touch-capable devices add another dimension to industry 4.0. Offering speed and versatility to a workforce’s capability on and off the factory floor, modern touch displays, like those found on smartphones and tablets, are the new norm by which workers interact with machinery.

6. Proliferation Of Intelligent Control Devices

By providing copious amounts of contextual automation data, smart control devices and sensors communicate with enterprise systems in a way that is both enlightening and cost-effective. The intelligence provided will serve an increasingly mobile and remote workforce in identifying inefficiencies, resolving issues before they become problems, and avoiding downtime events. Improved reliability and affordability of wireless network sensors will set a new standard for smart device interconnectivity while remaining largely untethered.

The proliferation of intelligent control devices is gaining momentum in manufacturing and other industries. Image: AG Silicon Germany

7. Collaborative, Affordable Robots

Cobots, collaborative, lightweight, and affordable robots, have become increasingly available to manufacturing sectors across a range of industries. With lower costs and more varied applications, these robots are following in the footsteps of the personal computer to bring size, power, and convenience to a broader community of small manufacturers.

As innovations in robotics make these tools more user-friendly and affordable, smaller manufacturing operations will benefit from their integration.

Gone are the days when reps had to make a trip to the manufacturing facility and display the latest brochures and pricing for robotics and automation products. Access to the latest innovations in these sectors are increasingly available online, where users of every background can conduct research, compare, and purchase equipment the same as they would a plane ticket.

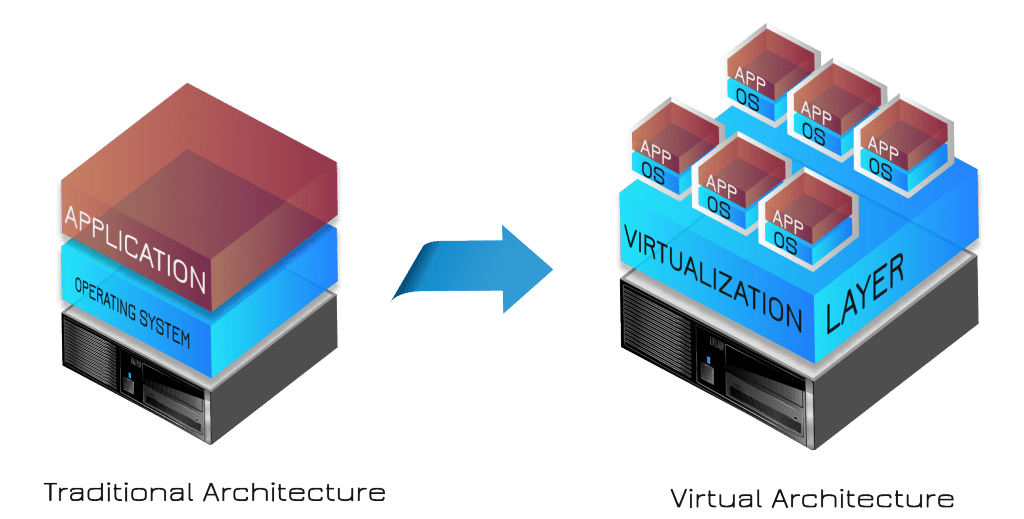

8. Virtualization

Increased functionality is allowing software-centric operations to be executed on fewer machines. As devices are progressively capable of running multiple operating systems and consolidating functions within one virtual architecture, overhead for manufacturing operations is reduced. Cheaper, more all-encompassing functionality will allow these operators to do more with less at every level of an enterprise.

Virtualization offers cheaper, more comprehensive architectures that allow manufacturing operators to do more with less.

9. Industrial Cybersecurity Management

As manufacturing operations increasingly become targets for cybercriminals and economic terrorists, enterprises of every size will need to take a much closer look at their established security protocols. Advances in cybersecurity are emerging to address industry-specific vulnerabilities and ensure at-risk operations receive the safeguards they require without impacting control system operations.

As manufacturing operations increasingly become targets for cybercriminals and economic terrorists, cybersecurity will demand more focused attention.

10. The Open Process Automation Forum

A consensus-based group of end-users, suppliers, system integrators, standards organizations, and academia, the Open Process Automation Forum was established by The Open Group to develop a standards-based, open, secure, and interoperable process control architecture. With recent additions of end-users and suppliers, the forum is gaining significant traction as a source of insight into the biggest challenges of process industries, including food and beverage, mining and metals, oil and gas, petrochemicals, pharmaceuticals, and many others.

Established by The Open Group as a standards-based, open, secure, and interoperable process control architecture, the Open Process Automation Forum is increasingly being relied upon by industry researchers, academics, and professionals.

One More For Good Measure: Integration Of AR/VR Into The Physical World

As Virtual Reality and Augmented Reality make significant strides in quality, user-experience, and affordability, the systems will be further integrated into the physical realm. By supplementing products with digital services, manufacturers are reshaping business models to incorporate these new applications. Virtual representations of physical products give end users a virtual twin with which simulation and predictive analytics can be leveraged to provide valuable and cost-saving insights. These simulated and augmented realities will offer new opportunities for training, maintenance, and problem scenarios to be explored without the physical event needing to take place.

About Encompass Solutions

Encompass Solutions is a business and software consulting firm that specializes in ERP systems, EDI, and Managed Services support for Manufacturers and Distributors. Serving small and medium-sized businesses since 2001, Encompass modernizes operations and automates processes for hundreds of customers across the globe. Whether undertaking full-scale implementation, integration, and renovation of existing systems, Encompass provides a specialized approach to every client’s needs. By identifying customer requirements and addressing them with the right solutions, we ensure our clients are equipped to match the pace of Industry.

- 8 Benefits of Quality Management | White Paper | Epicor Kinetic - March 8, 2022

- Epicor Kinetic Announces 1,000th Cloud Customer Milestone - February 14, 2022

- Epicor Financial Planner Product Release January 25, 2022 - January 25, 2022